MINIATURE MOTION GUIDANCE

- STANDARD TM SERIES

This standard width series of miniature linear motion guides is available with rails widths from 7mm to 20mm. These miniature guides offer low noise, compact design, high precision and corrosion resistance (stainless steel) making them ideal for medical equipment, semiconductor assembly, test devices etc.

There are two types of rail giving the option to bolt it from above (TMO) or below (TMU). The carriages can be specified with standard precision (N1) or high precision (H2) and standard preload (N1) or light preload (H2). Please see the table below for further details.

There is also a wider series (TMW) of rails which have higher load and moment capacities.

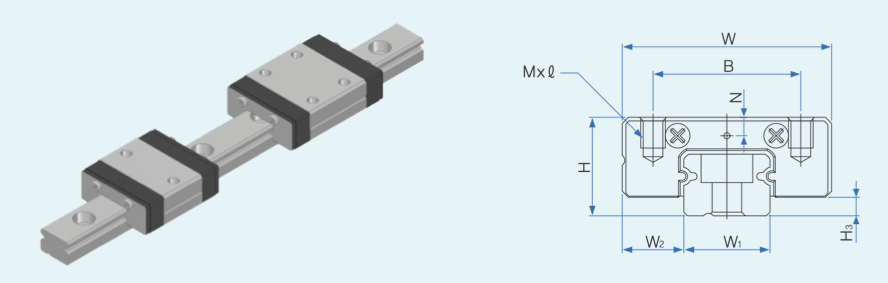

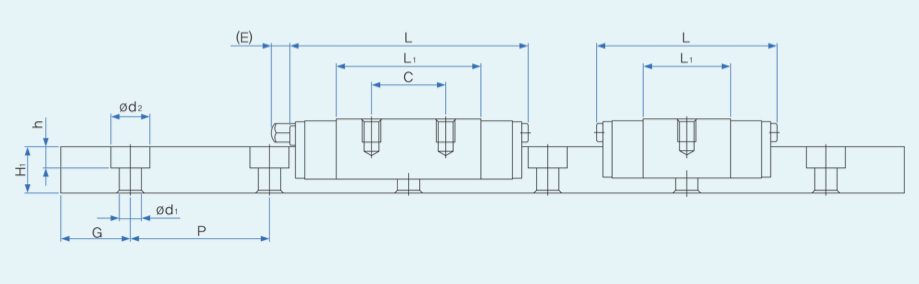

Carriage Dimensions

| Part Number | H | W | L | B | C | M x l | L1 | N | E | Grease ø | H3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| TM-7N | 8 | 17 | 24.3 | 12 | 8 | M2 x 2.5 | 14.1 | 1.5 | - | - | 1.5 |

| TM-7L | 8 | 17 | 31.8 | 12 | 13 | M2 x 2.5 | 21.6 | 1.5 | - | - | 1.5 |

| TM-9N | 10 | 20 | 31.3 | 15 | 10 | M3 x 3 | 20.7 | 2.2 | - | - | 2 |

| TM-9L | 10 | 20 | 41.4 | 15 | 16 | M3 x 3 | 30.8 | 2.2 | - | - | 2 |

| TM-12N | 13 | 27 | 34.9 | 20 | 15 | M3 x 3.5 | 21.3 | 2.7 | - | - | 3 |

| TM-12L | 13 | 27 | 45.4 | 20 | 20 | M3 x 3.5 | 31.8 | 2.7 | - | - | 3 |

| TM-15N | 16 | 32 | 44.4 | 25 | 20 | M3 x 4 | 27.7 | 3.1 | 4 | A-M3 | 4 |

| TM-15L | 16 | 32 | 44.4 | 25 | 20 | M3 x 4 | 27.7 | 3.1 | 4 | A-M3 | 4 |

| TM-20C | 20 | 40 | 39.8 | 30 | - | M4 x 6 | 22.2 | 4.2 | 4 | A-M3 | 5 |

| TM-20N | 20 | 40 | 51.8 | 30 | 25 | M4 x 6 | 34.2 | 4.2 | 4 | A-M3 | 5 |

| TM-20L | 20 | 40 | 69.8 | 30 | 30 | M4 x 6 | 52.2 | 4.2 | 4 | A-M3 | 5 |

All dimensions are in mm and loads are in N.

Rail Dimensions & Loads

The rail is available with either top fixing through holes (TMO) or bottom fixing threaded holes (TMU).

The maximum length for sizes 7 and 9 is 1000mm. For size 12 upwards the maximum length is 2000mm.

When two carriages are used in close contact, the moment capacity in directions Mp and My is increased - see table below.

| Part Number | W1 | W2 | H1 | G | P | d1 x d2 x h | TMU holes | C50 | C0 | Mp / My (1 block) |

Mp / My (2 blocks) |

Mr | Carriage Weight (g) |

Rail Weight (g/m) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TM-7N | 7 | 5 | 5 | 5 | 15 | 2.4x4.2x2.3 | M3 | 1197 | 1703 | 4.2 | 23.1 | 6.22 | 9 | 253 |

| TM-7L | 7 | 5 | 5 | 5 | 15 | 2.4x4.2x2.3 | M3 | 1631 | 2650 | 10.1 | 50.0 | 9.67 | 12.6 | 253 |

| TM-9N | 9 | 5.5 | 6 | 6 | 20 | 3.5x6x3.5 | M4 | 1721 | 2545 | 9.3 | 46.6 | 11.84 | 17.1 | 391 |

| TM-9L | 9 | 5.5 | 6 | 6 | 20 | 3.5x6x3.5 | M4 | 2375 | 4030 | 21.9 | 102.8 | 18.74 | 25.2 | 391 |

| TM-12N | 12 | 7.5 | 8 | 6 | 25 | 3.5x6.5x4.5 | M4 | 3023 | 3816 | 14.4 | 75.8 | 23.66 | 31.5 | 679 |

| TM-12L | 12 | 7.5 | 8 | 6 | 25 | 3.5x6.5x4.5 | M4 | 4246 | 6200 | 34.8 | 169.1 | 38.44 | 45.9 | 679 |

| TM-15N | 15 | 8.5 | 10 | 6 | 40 | 3.5x6.5x4.5 | M4 | 4540 | 5842 | 28.6 | 148.7 | 44.99 | 57.6 | 1071 |

| TM-15L | 15 | 8.5 | 10 | 6 | 40 | 3.5x6.5x4.5 | M4 | 6492 | 9737 | 73.5 | 351.2 | 74.98 | 85.5 | 1071 |

| TM-20C | 20 | 10 | 11 | 8 | 60 | 6x9.5x5.5 | M6 | 4512 | 5299 | 20.7 | 115.9 | 54.05 | 80.1 | 1572 |

| TM-20N | 20 | 10 | 11 | 8 | 60 | 6x9.5x5.5 | M6 | 6191 | 8328 | 50.2 | 252.7 | 84.94 | 119.7 | 1572 |

| TM-20L | 20 | 10 | 11 | 8 | 60 | 6x9.5x5.5 | M6 | 8396 | 12870 | 118.6 | 554.4 | 131.27 | 176.4 | 1572 |

Tolerance & Preload

| Size | Tolerance | Standard N1 (mm) | High H2 (mm) * |

|---|---|---|---|

| All sizes | Dimension tolerance of height H | ±0.040 | ±0.020 |

| All sizes | Difference in height H | 0.030 | 0.015 |

| All sizes | Dimension tolerance of width W2 | ±0.040 | ±0.025 |

| All sizes | Difference in width W2 | 0.030 | 0.020 |

* Size 20 is not available with H2 precision

| Size | Standard Preload N1 (µm) | Light Preload H2 (µm) |

|---|---|---|

| TM7 / TMW7 | -2 to +2 | -3 to 0 |

| TM9 / TMW9 | -2 to +2 | -4 to 0 |

| TM12 / TMW12 | -3 to +3 | -6 to 0 |

| TM15 / TMW15 | -2 to +2 | -10 to 0 |

| TM20 | -7 to +7 |

Related Products and Links