HOME > LINEAR BEARINGS > BALL BUSHINGS > TORQUE RESISTANT BALL BUSHINGS

TORQUE RESISTANT BALL BUSHINGS:

PDF Catalogue of Linear Bearings

|

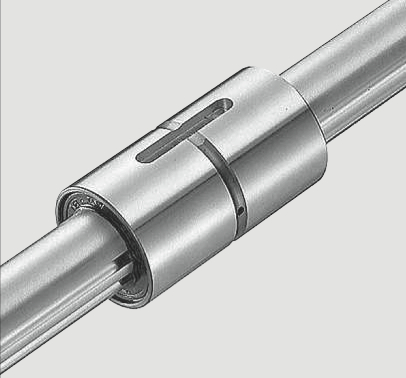

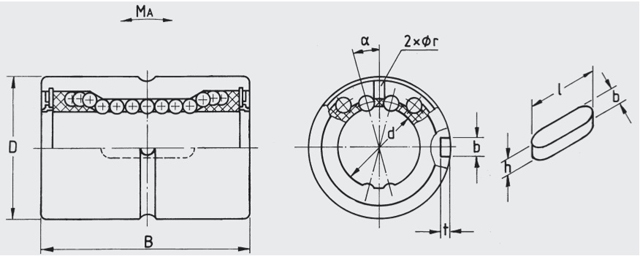

Our Torque Resistant Ball Bushings are a high precision linear motion system. The bushing as well as the shaft is equipped with ball guide grooves with special gothic profiles. This 4-point contact design offers a considerable high load capacity and a high rigidity through slight preloading. High torque values and shock resistance are ensured with this particularly compact space-saving design. Through optimized load carrying tracks and the polyamide ball retainer, a very smooth running is achieved. Use with Torque Resistant Spline Shafts. For lubrication the ball bushing is equipped with a lubrication hole. To retain the lubricant inside the bushing the seals at both ends are adapted to the profiled ball guide grooves. Sizes up to 25mm are also available in stainless steel - reference SSP4-5.. |

| Part Number | d | D | B | b | t | h | l | r | alpha | Torque Ct (Nm) |

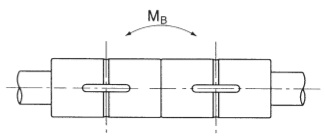

Torque C0t (Nm) | Load C (kN) | Load C0(kN) | MA |

MB (Nm) (see below) | Weight (kg) |

| SSP4-304 | 4 | 10 | 16 | 2.0 | 1.2 | 2.0 | 6 | - | 60 | 0.7 | 1.0 | 860 | 1220 | 2.0 | 10 | 0.01 |

| SSP4-306 | 6 | 14 | 25 | 2.5 | 1.2 | 2.5 | 10.5 | 1.0 | 60 | 1.5 | 2.4 | 1.22 | 2.20 | 5.1 | 40 | 0.02 |

| SSP4-308 | 8 | 16 | 25 | 2.5 | 1.2 | 2.5 | 10.5 | 1.5 | 60 | 2.1 | 3.7 | 1.45 | 2.87 | 7.4 | 50 | 0.02 |

| SSP4-310 | 10 | 21 | 33 | 3.0 | 1.5 | 3.0 | 13 | 1.5 | 60 | 4.4 | 8.2 | 2.73 | 5.07 | 18.0 | 116 | 0.06 |

| SSP4-314 | 13 | 24 | 36 | 3.0 | 1.5 | 3.0 | 15 | 1.5 | 25 | 21 | 40 | 2.7 | 4.9 | 13.7 | 109 | 0.07 |

| SSP4-316 | 16 | 31 | 50 | 3.5 | 2.0 | 3.5 | 17.5 | 2.0 | 25 | 60 | 110 | 6.15 | 11.2 | 46 | 299 | 0.15 |

| SSP4-320 | 18.2 | 32 | 60 | 4.0 | 2.5 | 4.0 | 26 | 2.0 | 16 | 85 | 136 | 8 | 11.5 | 64 | 500 | 0.20 |

| SSP4A320 | 20 | 35 | 63 | 4.0 | 2.5 | 4.0 | 29 | 2.0 | 16 | 105 | 194 | 8.9 | 16.3 | 110 | 560 | 0.22 |

| SSP4-325 | 23 | 37 | 70 | 5.0 | 3.0 | 5.0 | 33 | 3.0 | 16 | 165 | 244 | 12.6 | 16.4 | 106 | 830 | 0.22 |

| SSP4A325 | 25 | 42 | 71 | 4.0 | 2.5 | 4.0 | 36 | 3.0 | 16 | 189 | 346 | 12.8 | 23.4 | 171 | 1029 | 0.33 |

| SSP4-330 | 28 | 45 | 80 | 7.0 | 4.0 | 7.0 | 41 | 3.0 | 16 | 295 | 420 | 19 | 23.7 | 185 | 1470 | 0.35 |

| SSP4A330 | 30 | 47 | 80 | 4.0 | 2.5 | 4.0 | 42 | 3.0 | 16 | 307 | 439 | 18.6 | 23.2 | 181 | 1470 | 0.36 |

| SSP4-340 | 37.4 | 60 | 100 | 10.0 | 4.5 | 8.0 | 55 | 4.0 | 16 | 650 | 900 | 31.4 | 38.3 | 365 | 2940 | 0.81 |

| SSP4A340 | 40 | 64 | 100 | 6.0 | 3.5 | 6.0 | 52 | 4.0 | 16 | 674 | 934 | 30.8 | 37.5 | 358 | 2940 | 0.95 |

| SSP4-350 | 47 | 75 | 112 | 15.0 | 5.0 | 10.0 | 60 | 4.0 | 16 | 1420 | 3240 | 47 | 75.7 | 710 | 4400 | 1.50 |

| SSP4A350 | 50 | 80 | 125 | 8.0 | 4.0 | 7.0 | 58 | 4.0 | 16 | 1291 | 2955 | 40.3 | 64.9 | 690 | 4084 | 1.90 |

| SSP4-360 | 56.5 | 90 | 127 | 18.0 | 6.0 | 11.0 | 68 | 4.0 | 16 | 2100 | 4800 | 58 | 127 | 1300 | 8800 | 2.50 |

| SSP4A360 | 60 | 90 | 140 | 12.0 | 5.0 | 8.0 | 67 | 4.0 | 16 | 1577 | 2629 | 47.7 | 79.5 | 881 | 5473 | 2.30 |