HOME > TOLERANCE RINGS

TOLERANCE RINGS - Guide, Technical Information & Index:

|

|

|

Short lead times & small minimum order quantities. Can also be made to your requirements. Select the type AN or BN from above or choose a size from the right hand navigation bar. |

||

What is a tolerance ring?

A tolerance ring is a corrugated metal strip that acts as an interface between two mechanical objects, to secure one to the other by interference fit. The corrugations (or waves) of the tolerance ring act like springs, fastening the two components together.

They have been used with great success for many years and offer many technical and economic advantages.

What are tolerance rings made from?

Spring Steel Strip or Stainless Steel (AISI 301) Strip - the majority from Stainless Steel.

How do I specify the tolerance ring I need?

There are two basic types of ring & the simplest way to remember is this:

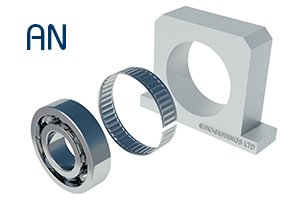

AN type is used for holding a bearing / object into a housing. The largest diameter is variable enabling the housing diameter to be varied.

BN type is used for holding a bearing / object onto a shaft. The smallest diameter is variable enabling the shaft diameter to be varied.

Following this rule, you can easily select the ring you want for other jobs. For example a knob is fitted onto a shaft using a BN type tolerance ring.

Photo of AN type / Diagram of AN type

Photo of BN type / Diagram of BN type

What sort of torque can be transmitted - will they slip?

See the data sheets (listed on the right hand navigation bar) for the dimensions of the mating parts and the torque transfer capability. Please note the torque transfer values should only be used as a guide as the component materials may affect the values achieved.

If the torque stated is exceeded the tolerance ring will slip - this can be a means of preventing damage.

The allowable torques are high.

How do I fit tolerance rings?

AN - housing variable (HV): The tolerance ring is placed in the housing bore with the flat edge on the outside of the ring and then the bearing is pressed into the bore (ensuring it remains at right angles). The AN type rings are made in a slightly open condition which allows them to grip the bore of the housing during assembly.

BN - shaft variable (SV): The tolerance ring is placed over the shaft and the shaft is pressed into place. The flat edge is on the inside of the ring.

What other advantages do tolerance rings have?

- rapid assembly help to lower costs

- permit larger machining tolerances

- high torque capabilities / provide overload protection

- compensate for different rates of thermal expansion

- eliminate expensive features on parts (for example keyways, pins, screws etc)

- absorb vibrations

- resist corrosion

- compensate for misalignment

What temperature range can they operate at?

Stainless Steel: The spring qualities of the stainless steel tolerance ring does not deteriorate when operating in temperatures of up to 250ºC.

Carbon Steel: The maximum continuous operating temperature for the carbon steel tolerance rings is 120ºC.

Can I use them in tandem to achieve a greater load capacity?

Where an application requires greater load than that provided by one tolerance ring, it is possible to fit two or more tolerance rings in tandem until the sum of their load ratings exceeds the load to be carried. However, the tolerance rings must be separated by flanges / upstands to prevent the rings slipping over each other.