HOME > PLAIN SLIDING LINEAR BEARINGS > PARALLEL SHAFTING

DRY SLIDING (PLAIN) BUSHES - PARALLEL SHAFTING:

Edge Loading

Sleeve-type linear motion bearings, more so than ball bushings, requires parallel shafting to be aligned as closely as possible to avoid edge loading. Edge loading can cause higher than expected friction and subsequent wear.

If there are side loads and moment loads which have not been taken into consideration relative to bearing or shaft spacing, you may experience at least one of these issues:

1. Binding

2. Sticking

3. Excessive system friction and bearing wear

Ask us if you have any application questions.

![]()

Ratio for Moment Loading:

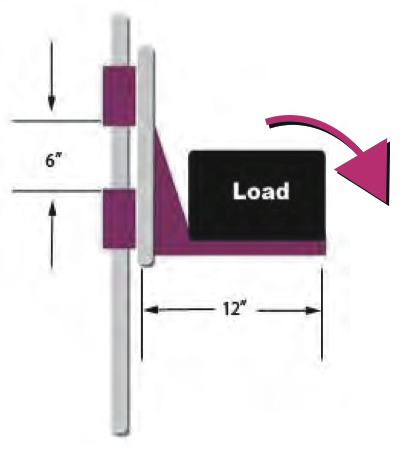

a) 2:1 Ratio for Moment Loading in the Vertical (Z) axis:

To prevent edge loading, the distance between bearings on 1 vertical shaft must be spaced a minimum of 1/2 the distance of the moment arm. See diagram. The optimal ratio is 1:1

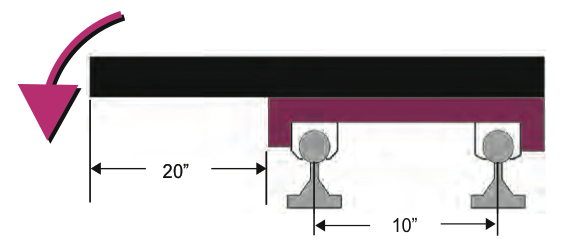

b) 2:1 Ratio for Moment Loading in the Horizontal (X,Y) axis:

In the horizontal axis the distance between the shafts must be a minimum of 1/2 the distance of the moment arm. See the example below. Again the optimal ratio is 1:1.