HOME > COMBINED ROLLER BEARINGS > PRECISION COMBINED ROLLER BEARINGS

PRECISION COMBINED ROLLER BEARINGS

The following article was published in PT Review Magazine. The original article can be read here.

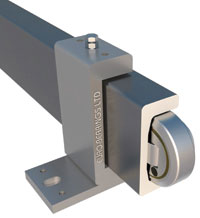

When we talk about ‘precision’ in this context we are not here talking about a tighter set of tolerances relevant to the internal *construction of the full complement cylindrical roller bearing but rather the tightening of the external running tolerance between the outside diameter of the combined roller bearing and the ‘mouth’ of the mating steel profile.

This is achieved by accurately milling the ‘mouth’ of the hot rolled steel section, which of course increases the dimension of the mouth, and then increasing the outside diameter of the bearing to reduce the running clearance from the normal clearance to a precision clearance.

For example and comparison:

This is useful for a designer to know:

The tighter running tolerance between the bearing and the rail makes it suitable for applications requiring higher positional precision, whilst still offering the high load capacity of the combined roller system and the cost benefits over many other linear motion systems.

For example:

- A horizontal ‘drawer’ system carrying ISO tooling for machine tools where pick-up positon it critical.

- A horizontal sliding pick and place system that cannot be economically built using machine tool type sliding systems.

- Other lower accuracy robotic systems, packaging, palletising, de-palletising, pick and place.

*(Please note both Euro-Bearings standard and precision combined roller bearings are made to ISO ‘Normal’ tolerances for radial bearings)

| Precision Combined Bearings |  |

| Precision Channel / Profile Data | |