“Tolerance Rings are simple and inexpensive fasteners that enable easy assembly and also facilitate disassembly. Other benefits include torque control, compensation for thermal expansion and a reduced requirement for machining of the connecting parts.“

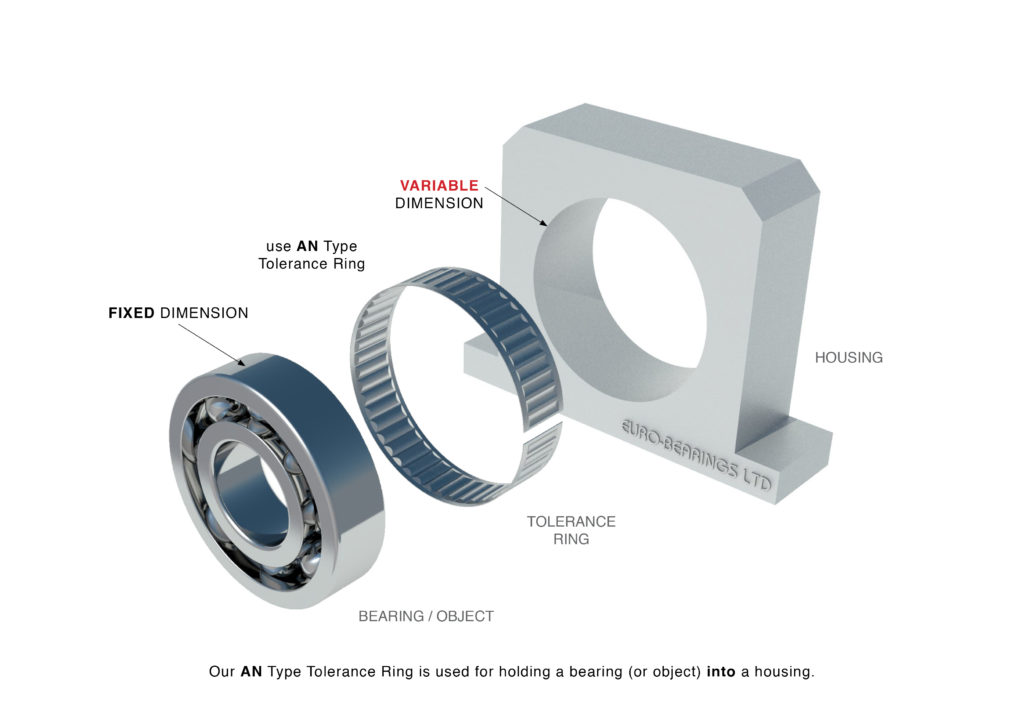

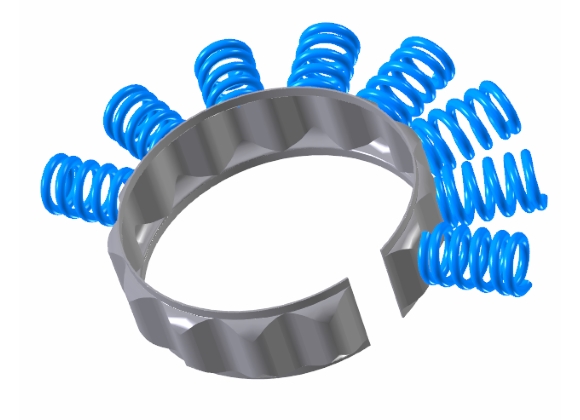

Tolerance rings are corrugated stainless steel rings that are used to connect two components. The corrugations around the circumference of the tolerance ring act like springs and consequently apply a pre-load force between the parts being assembled. One major advantage of tolerance rings over gluing together or press fitting parts is that they can be easily assembled AND disassembled. This enables components to be reused and hence saves money.

Tolerance rings allow the transmission of high torques and can be used over a wide range of temperatures. They can also be used to provide protection against damage when the torque becomes too high. Another advantage of tolerance rings is that they can compensate for differences in thermal expansion between the parts they connect.

Advantages of Tolerance Rings

- Quick & easy assembly and disassembly

- Compensation for thermal expansion (in some cases up to 450ºC)

- Secure connection over a range of tolerances reducing requirement for post processing of components

- Reduced vibrations & oscillations due to the spring effect of the Tolerance Ring which also helps with noise reduction

- Cost savings in assembly and damage protection

- Facilitate torque control

- Wide range of standard sizes on quick delivery

- Customised solutions possible

Example applications for Tolerance Rings

- Electric Bike Motor – the stator is fastened using a tolerance ring. Time and money is saved as there is no curing time for an adhesive and the stator does not require post processing due to a wider range of permissible tolerances. Thermal expansions of the different materials are also compensated by the tolerance ring.

- Pump – Tolerance rings can be used as a simple and inexpensive fastener to connect the pump impeller or rotor to the drive shaft. They offer the added benefit of compensating for variations in thermal expansions between the different materials.

- Conveyor Rollers – This application requires the connection of a drawn steel tube with the cast aluminium shaft of the driven roller. There are two benefits to using a tolerance ring to connect these components. Firstly the tolerance ring allows the connecting parts to be finished to a lower precision, hence eliminating the need to further work the items. Secondly the tolerance ring compensates for the different thermal expansions of the steel tube and the cast aluminium. Furthermore, the assembly of the components is simplified and the torque transfer is maintained even with the lower precision of the parts.

Full details on the range of Tolerance Rings available from Euro-Bearings Ltd can be found here.