Euro-Bearings Ltd stocks a wide range of linear motion products. We are able to offer a variety of products in stainless steel when corrosion resistance is required. Our technical sales team have many years of expertise and are able to guide you with selecting the best product for your application.

Stainless Steel Linear Bearings and Stainless Steel Shafts:

These linear bearings offer high corrosion resistance due to the special characteristics of martensitic stainless steel. The hardening process leads to an increased service life and a higher load capacity.

The linear bearings are available in closed (KB50) and open (KB53) types along with a range of round flanged versions including FK10 (standard length), FK90 (tandem length) and TF00 (centre flanged).

In addition to this, the SK-n super ball bushings and CLBn compact ball bushings are available with electroless nickel coating to the bush and stainless steel balls. Alternatively the LBBRn is a stainless steel linear bearing with compact design.

The X90CrMoV18 stainless steel shafts are hardened and polished linear bearing shafts, and are available from ø3mm to ø50mm. They can be supplied cut to length or machined to your requirements.

Stainless Steel Linear Guide Rails:

The profiled rail linear guides of the motion guidance systems offer high precision and smooth operation.

All of the Miniature Motion Guidance range (sizes 7 to 20) are made from stainless steel as standard.

The Aluminium Motion Guidance range is also corrosion resistant as the raceways and balls are made from stainless steel. It is available in sizes 15, 20 and 25.

The Track Guidance System can also be supplied as corrosion resistant – the carriages can be supplied with stainless steel bearings and the rails with stainless steel shafts.

Stainless Steel Spline Nuts and Shafts:

The SSP and SPF spline nuts can be supplied in stainless steel with a resin cage, for diameters up to 25mm. The ground spline shaft is available in stainless steel for the corresponding sizes. Other diameters are available with black chrome plating on request.

Stainless Steel Vee Bearings:

When used in conjunction with the Vee rail and Vee bushings, the Vee bearings linear system is suitable for harsh environments with high speed capabilities, medium accuracy and low noise. The Vee bearings, Vee bushes and Vee rails are all available in stainless steel.

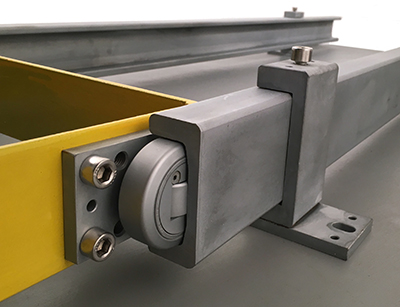

Corrosion Resistant Combined Roller Bearings and Rails:

For heavy duty linear motion applications, Euro-Bearings Ltd’s Combined Roller Bearings are often the best solution.

The bearings can be Thin Dense Chromium (TDC) coated to provide corrosion resistance and the rails can either be TDC coated for maximum protection, or galvanised / painted. If the rails are galvanised or painted, the surface of the rail in contact with the bearing must remain free of coating to preventing flaking. The standard combined roller bearings are available from ø52mm to ø149mm, with sizes up to ø390mm in the Jumbo range. The rails are available in C or I sections and are cut to the required length.

The bearings and rails can be configured for vertical, horizontal or cantilevered applications and can be used to make telescopic arrangements too. Example arrangements can be found on our website. This system is particularly tolerant of dirt as the bearings are sealed.

Conclusion:

With a wide range of corrosion resistant linear bearings to choose from, you can be certain to find something suitable for your linear motion application. Our technical sales are always happy to help, so please call or email to discuss.