Euro-Bearings Ltd specialises in bearings for linear motion and can offer technical support when designing and specify products. With over 40 years’ knowledge of combined roller bearings, you can be sure that you are asking the experts.

How to use Combined Roller Bearings?

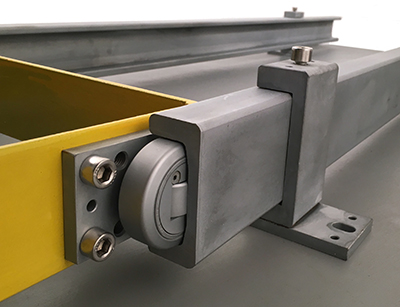

Combined Roller Bearings were originally designed for forklift trucks. The assembly consists of two bearings in one, hence “combined”. The radial bearing carries the main load whilst the smaller axial roller resists any side load to help keep the system running true.

A simple horizontal application requires just two special profiled rails and four standard bearings. The bearings can be supplied welded to mounting plates so they can be bolted into place. The combined roller bearings are available from ø52.5mm to ø390mm making them suitable for loads of just ten kilograms right through to tens of tonnes.

More complex applications include vertical, telescopic and cantilevered arrangements, and they can even be used on all 3 axes to make an XYZ machine. See our application examples for inspiration.

How to select the size?

Every application is different and it is important to check the loads to ensure the correct bearing is specified. In some instances it makes sense to use more rails or bearings to share the load, for example on a vehicle chassis, rather than simply increasing the size of the bearing.

The critical factor is the Hertzian Pressure which is the point load exerted on the profiled rails by the bearings. This force must be limited to prevent the deformation of the rails. The Hertzian Pressure can be calculated using Moment-Balance. In most instances, simple formulae (given on our website) can be used to calculate the force on the bearings and the size of bearing can be selected from our Hertzian Pressure table.

Our technical sales team can support you with this together with design recommendations.

How to set up the rails?

Setting up the system accurately will ensure that the Combined Roller Bearings operate to the best of their ability. Ideally the rails should be absolutely parallel with a clearance between the bearing and rail of 0.3mm to 1.0mm. It is important to test the clearance of the system over the entire length to ensure the axial rollers do not bind in use.

The rails are made from S450J2 steel which is similar to S355 structural steel. The rails can be welded or bolted into place. If it is difficult to set up the system accurately then it can be useful to weld tabs with slotted holes onto the rails to facilitate more accurate adjustment.

Should further adjustment be required, then our eccentric adjustable or shim adjustable bearings can be specified, or the mounting plates can be shimmed from behind.

How to weld the bearings?

The combined roller bearings incorporate a weldable hub made from C22E. The unit does not have to be disassembled for welding, but heat from the weld should be kept to a minimum. The hole into which the bearing is fitted should be 50 to 100 microns larger than the diameter of the hub. It is important to ensure the axial roller is orientated correctly before welding the back using a continuous 45º weld fillet. Normal mild steel (non-alloy) welding techniques can be used. Alternatively the bearings can be supplied pre-welded to mounting plates for ease of assembly.

How to set up the adjustable bearings?

The eccentric and shim adjustable bearings have adjustable axial rollers to alter the height (h) of the bearings. The eccentric type has a splined shaft which can be finely adjusted to achieve the required clearance. There is a video showing how to do this on our website. The height of the shim adjustable type can be altered by placing shims behind the axial roller. When the final height is achieved, the screws should be thread locked to ensure they are secure.

How to protect the Bearings and Rails?

In harsh environments it might be necessary to protect the bearings from rust. This can simply be in the form of shielding or an anti-rust spray, or it may be necessary to coat the bearings to provide corrosion resistance.

The bearings can be supplied with Thin Dense Chromium (TDC) plating which offers a high level of corrosion protection. This is available for all sizes and the mounting plates can be coated too.

The rails can be painted or galvanised to offer protection, but the surface in contact with the bearings must remain bare as the force exerted by the bearings is likely to damage these coatings. The bare steel can be lightly oiled to prevent rust. Alternatively, if full corrosion resistance is required, the rails can be TDC coated over their entire surface.

How to grease and maintain the Bearings?

In a dry environment, such as a warehouse, the rails and bearings can be lightly oiled to keep the surfaces free from rust.

The bearings should be inspected and re-lubricated as required every 6 months. The standard bearings (apart from the smallest 4.053 bearing) have a lubrication hole which is plugged with a grub screw.

If the bearings are in continuous use or harsh conditions, they should be checked more frequently.

A grade 3 bearing grease should be used (e.g. Shell Gadus).

How to replace the bearings?

Should the bearings need to be replaced, the screws holding the bearing to the weldable hub can be undone and a new bearing slid on. A video on our website shows this procedure. The bearing needs to be square to the hub for ease of assembly.

If the bearing is welded to a mounting plate, the whole bearing and plate unit can be easily replaced. There is a standard range of rectangular and square plates, or alternatively a custom plate can be specified.

How fast can the Combined Roller Bearings travel?

The linear speed should less than 1.1m/s for optimum performance. For short intervals and moderate loads, a maximum speed of 1.5m/s is permitted but this may affect the service life.

When to specify Precision (PR) Combined Roller Bearings?

The precision bearings offer a tighter tolerance between the bearings and the rails. In most applications the standard bearings will suffice, but in some cantilevered applications it may be preferable to have a tight tolerance to limit the play in the system.

When to specify High Temperature Bearings?

The standard combined roller bearings can be used for temperatures of up to 80ºC. When the temperature is continuously above 80ºC, we recommend the use of High Temperature (HT) bearings. The HT bearings can operate in temperatures up to 200ºC.

What is S450J2 Steel?

S450J2 is a non-alloy steel that has been developed specifically for use with bearings. The addition of Niobium (Nb) and Vanadium (V) improves both the tensile strength and yield strength which increases the allowable Hertizian Pressure (point load exerted by the bearing).

What seals are used?

The majority of the combined roller bearings feature a ZRS seal which is a metal-rubber hybrid seal. The seals help to prevent dust, water and debris from entering the bearing and retain the grease inside.

What are the Benefits of Combined Roller Bearings?

There are many benefits to Combined Roller Bearings, with their versatility probably being the main one.

- Combined Roller Bearings are used with matching C or I section profiled rails to provide a simple yet versatile linear motion system that can be used in many applications and environments.

- The Combined Roller Bearing handles both the axial and radial forces in one unit hence reducing the number of working parts required.

- The axial roller runs on the web of the steel to provide lateral guidance. This helps to keep the slide running true and prevents jamming or crabbing.

- The bearings and rails can be used horizontally and vertically, and can also be arranged telescopically in both orientations to allow for full extension.

- The bearings can be supplied pre-welded to a mounting plate and then simply bolted on for ease of assembly. Alternatively they can be welded directly to the structure for a more compact arrangement.

- The system can be used in harsh environments and offers good resistance to dirt. High temperature bearings can be specified.

- The Combined Roller Bearings can be coated to provide corrosion resistance.

- A precision (PR) version is available for applications requiring higher positional accuracy.

- Combined Roller Bearings offer a robust heavy duty linear system at a reasonable price which is easy to set up and maintain.

What applications can Combined Roller Bearings be used for?

Typical applications for combined roller bearings include:

- Oil drilling and exploration equipment

- Marine cable and pipe-laying equipment

- Palletisers and packing machines

- Goods & vehicle lifts

- Material handling equipment

- Furnace chargers/dischargers

- Concrete and aggregate conveyors

- Brick and concrete block making machines

- Machine tool positioning and storage

- Agricultural equipment

- Specialised vehicles and trailers

- Theatre and film applications

- Medical equipment

- Forklift truck attachments

- Warehouse automation

A range of application examples are shown on our website including cantilevered, 1 and 2 stage telescopic, and full extension arrangements.

Want to find out more? Or ask another question? Contact our Technical Sales team.