Combined Roller Bearings were originally designed to be used in forklift truck masts. However, today they are used in a variety of applications (horizontally and vertically) and in a huge range of industries.

The smallest bearing is just 52.5mm in diameter and when used in conjunction with the corresponding steel profile, each bearing offers a load capacity of approximately 550kg. At the top end of the range the largest bearing is 390mm and has a capacity of over 30 tonnes.

The primary benefit of a Combined Roller Bearing over a standard track roller bearing is the integral side thrust roller bearing. This small roller is able to carry lateral loads and ensures free movement of the system.

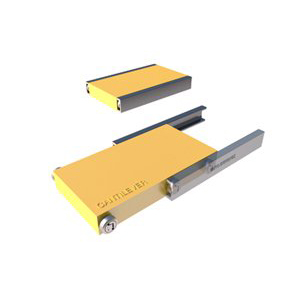

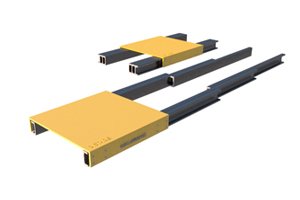

To make a complete slide you simply need 2 rails and 4 bearings. The bearings can be welded directly to the structure or can be supplied pre-welded to a mounting plate and simply bolted into place. More complex, telescopic systems can be made by using additional rails and bearings to create further stages.

The application examples below show how versatile this sliding system is.

|

|

|

|

|

|

Being so versatile, combined roller bearings can be used in many applications including:Please click an image for more details.

- Lifting & Handling Equipment

- Offshore Cable & Pipe Laying

- Specialised Vehicles

- Packing Machines

- Furnace Loaders

- Agricultural Equipment

If you think you might have an application for Combined Roller Bearings, please contact our technical sales team. We have many years of experience and our team includes Engineers and Designers.